- Home Page

- Company Profile

-

Our Products

- Industrial Chillers

- Blow Moulding Chiller

- Water Cooled Chillers

- Acid Chillers

- Injection Moulding Chiller

- Beverage Chillers (Juice Chillers)

- Chiller for Extrusion Lines

- Chiller For Anodizing

- Anodising Chiller

- Chiller For Anodising

- Co2 Gas Chillers

- Ammonia Milk Chillers

- Bio Gas Chillers

- Bottling Plant Chillers

- Industrial Process Chillers

- Low Temperature Chillers

- Chiller For Electroplating

- Batching Plant Chiller

- Air Chiller

- Air Cooled Scroll Chiller (Single Compressor)

- Chilling Plant Turnkey Project

- Blown Film Plant Chillers

- Industrial Scroll Chillers

- Semi Hermetic Chiller

- Laminating Chillers

- Screw Chillers

- Scroll Water Chiller

- Cooling Tower

- Chilling Plants

- Oil Chillers

- Scroll Chiller

- Glycol Chillers

- Chillers

- Screw Type Water Chiller

- Air Cooled Chillers

- Industrial Chillers

- Extra Links

- Contact Us

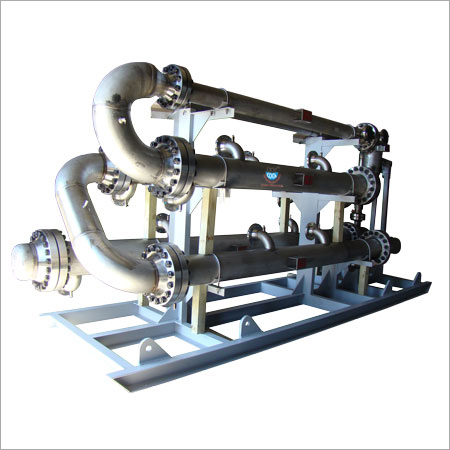

Ammonia Milk Chillers

500000 INR/Piece

Product Details:

- Material Metal

- Usage Industrial

- Product Type Ammonia Milk Chillers

- Condition New

- Click to View more

X

Ammonia Milk Chillers Price And Quantity

- 500000 INR/Piece

- 1 Piece

Ammonia Milk Chillers Product Specifications

- New

- Metal

- Ammonia Milk Chillers

- Industrial

Ammonia Milk Chillers Trade Information

- Cash in Advance (CID) Cheque Cash Advance (CA)

- 1 Week

- Wooden Packing, As per product

- Western Europe Central America North America South America Middle East Eastern Europe Asia Australia Africa

- All India

- ISO 9001: 2015

Product Description

We provide Ammonia Milk Chillers, which have been completed to offer the users all the benefits of a long-lived investment and the utilization of an environmental friendly liquid. The utilization of ammonia, will increase the machine performance with a total benefit on the running expenditures. Ammonia Milk Chilling machine that we deal in stand for one of the accomplish-able ways to cut down the environmental effect of the cooling aspect (GWP = 0 and ODP = 0).

The technology used in this machine is peculiarly detailed. These offer the clients the widest prospect of choice. Offered range is accessible in various set-ups in accordance with the individual specification of the customers' and project demands.

- Offered ambit is incorporated with devices, which have 1, 2, or 3 screw compressors in side by side.It is manageable to provide packaged chillers with reduced refrigerant charge (up to 75 kg, as for Italian conceptions).

- Available with assorted configurations, which also comprise of: PHE/S&T/S&P heat exchangers.

- Flooded (FL) system units or Direct Expansion (DX) units.

- The control is constituted by an electronic modular or with the utilization of a PLC. The chillers can be provisioned with or without the consolidation of electrical board.

- It is appropriate for outdoor as well as indoor installations.

Ammonia Milk Chillers can be configured for water cooling or the cooling done - at negative temperatures - of brine solvents, be they are supported on salt solutions or glycol. The units are assembled with the self supportive painted steel framework that is welded with press-bent metal sheet side view. Every part of the steel framework is coated with epoxy powder.

Features:

- Custom-made solution

- Reduced maintenance cost

- Durability and strength

- Simple installation

- Immaculate cooling

- Performance directed

- Elementary operations

- Structural efficiency

- Robust construction

FAQ

1. An ammonia milk chiller is what?

Ans - A type of cooling system called an ammonia milk chiller is intended to maintain a constant temperature for milk and other dairy products. It operates by circulating cold ammonia gas via a network of copper coils and pipes and employs anhydrous ammonia as the refrigerant.

2. How does a milk chiller using ammonia operate?

Ans - After entering the chiller and being compressed, the ammonia gas is subsequently transferred via a number of coils and pipes. The ammonia gas collects and releases heat energy as it travels through the coils and pipes, chilling the milk and other dairy products as a result.

3. What advantages do ammonia milk chillers offer?

Ans - Maintaining milk and other dairy products at a constant temperature is easy and dependable with an ammonia milk chiller. Additionally, it helps to keep food secure from deterioration and lower energy expenses.

4. Does employing an ammonia milk chiller have any drawbacks?

Ans - The biggest disadvantage of employing an ammonia milk chiller is that because it uses anhydrous ammonia as the refrigerant, using one can be dangerous. To reduce any safety issues, it's crucial to make sure the system is installed and maintained correctly.

5. How frequently should a milk chiller for ammonia be serviced?

Ans - To make sure it is working effectively and safely, an ammonia milk chiller needs to be serviced frequently. Checking the refrigerant levels, looking for leaks, and cleaning the coils and pipes should all be part of routine maintenance.

Enter Buying Requirement Details

Other Products in 'Industrial Chillers' category

|

DRYCOOL SYSTEMS INDIA (I) P. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |