- Home Page

- Company Profile

-

Our Products

- Industrial Chillers

- Blow Moulding Chiller

- Water Cooled Chillers

- Acid Chillers

- Injection Moulding Chiller

- Beverage Chillers (Juice Chillers)

- Chiller for Extrusion Lines

- Chiller For Anodizing

- Anodising Chiller

- Chiller For Anodising

- Co2 Gas Chillers

- Ammonia Milk Chillers

- Bio Gas Chillers

- Bottling Plant Chillers

- Industrial Process Chillers

- Low Temperature Chillers

- Chiller For Electroplating

- Batching Plant Chiller

- Air Chiller

- Air Cooled Scroll Chiller (Single Compressor)

- Chilling Plant Turnkey Project

- Blown Film Plant Chillers

- Industrial Scroll Chillers

- Semi Hermetic Chiller

- Laminating Chillers

- Screw Chillers

- Scroll Water Chiller

- Cooling Tower

- Chilling Plants

- Oil Chillers

- Scroll Chiller

- Glycol Chillers

- Chillers

- Screw Type Water Chiller

- Air Cooled Chillers

- Industrial Chillers

- Extra Links

- Contact Us

Showroom

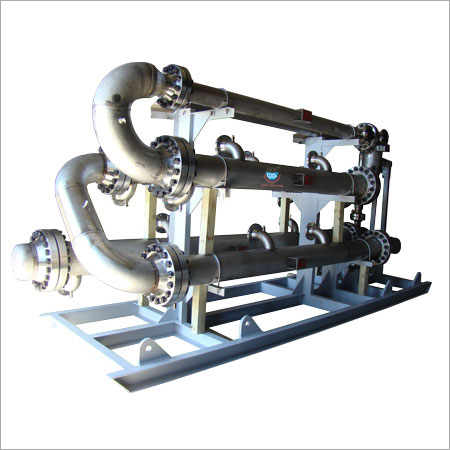

Technically, our industrial chillers are named as a system of cooling, which chills dehumidifies air or treated liquid in industrial as well as commercial areas. The chiller deploys absorption cycle or vapor compression, any one to chill. Further, from area chilling to treated applications, our system is superior to all.

Screw chillers offer process and comfort cooling, heat and cooling recovery as well as deliver efficient and unrivaled heating for wider industrial and commercial usages, as well. The system amalgamates chiller with coil units of fans for productive interior chilling and heating, while expanded limit industrial units offer proper temperature control for bigger scale healthcare, scientific or storage demands.

A productive cooled scroll water from us can enable you to bring the working budget on scale. The system is delivered completely, which is most reliable, efficient as well as quiet chiller that is accessible in todays world. Integrated technology in the chiller is sound for introduction in noise sensitive environs along with good pressure levels. The chiller is profitable for evaporative condenser, remote air-cooled and water cooled uses.

Cooling Tower is completely composed of fiber reinforced plastic outfitted with polypropylene blossom nozzles for even spacing. The nozzles ate simply viable even while in operating condition. Pump power are moderated since gravity will suffice water channel after the air is strained crosswise over [Horizontally] the stream of water (that is Vertical) are titled cross stream sort cooling tower.

Chilling Plants provide water chillers for chilling the natural liquid from temperature between 45 C to +4 C. These are known containerized cool water plants. More productive for lesser solid temperatures are chillers, water and system chilling for diversified used. These plants are outfitted with uncommon system of ice bank gathering ice over the plate or tuber thermal exchangers.

Our Oil Chillers are exceptionally intended to chill oil straightforwardly via refrigerant-to-oil thermal transferring circuits. These are intended to deal with the oil penetrating the evaporator at elevated than typical temperatures, even the passage oil temperature additionally being significantly elevated than the standard procedure cooling uses.

Our Scroll Chiller has great execution as well as highlights normal of more expensive and larger chiller. This offers large advantages for little to mid measured structures. Our chiller, which is outfitted with numerous hermetic scroll compressors make it suitable for different stress uses such as industries, hospitals, hotels, medium office spaces and more.

Our Glycool Chillers are composed and outlined for extra low as well as least temperature applications. Secondary and main chilling circuits are completely slip attached and available, as well, in both water cooled and air cooled kinds. They are intended for zero misuse possibility. Fluid specifications use material clearly in compliance to specific process cooling requirements.

We offer Chillers that possess capability of refrigerant-storage and eliminates the requirement of added space, external storage tank, etc. The advance design renders excellent advantages while installing and operating the mentioned gadget. These are available with both compressors like single and multiple along with greater cooling capacities for water and air.

Primarily used as a device for facilitating exchange of thermal energy in a closed loop system between water and and a refrigerant, Screw Type Water Chillers are one of the most types of water chillers used at industrial levels. One of the most prominent usage scenarios of these systems is in making air conditioning arrangements of modern infrastructure like in commercial buildings to cool the air and also regulate the temperature of equipments. They are also found to be particularly effective in cooling separate thermodynamic environs like the multiple room systems in hotels, and are thus known to be an ideal solution.

Provided range of Air Cooled Chillers are acknowledged for their long working life, high operating speed and utilization of imported quality compressor. These chillers are easy to install and maintain. Utilization of CFC free refrigerants is one of their main aspects.

|

DRYCOOL SYSTEMS INDIA (I) P. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |